incl. 20% VAT

incl. 20% VAT

Beal ropes are among the best known in the world. And for good reason.

The brand is the largest global manufacturer of kernmantel ropes. For alpine sports, rescue services, work at heights and for industry.

The traditional brand is also responsible for many pioneering innovations, such as the “UniCore” manufacturing process and the “Dry Cover” and “Golden Dry” impregnation technologies.

The company also produces webbing slings, cordalettes and climbing harnesses.

However, the focus remains the same. Today, the brand produces 12 million meters of finished “knitting” per year. On the one hand at the main plant near Vienne in western France. And also at the plant in Madagascar.

The four best-known models each have the typical innovations of the world market leader. Such as triple certification, impregnation technology or diameter benchmarks.

History

Beginnings

1951, the year it all began. Pierre and Janine Beal found their company in Vienne. They are only indirectly involved with ropes. They produce cords for jackets and shoelaces.

In 1974, his son Michel joins the company. He is a passionate climber. With a clear vision of the future, he switches to the production of polyamide ropes.

However, he lacks the know-how. The involvement of mountaineering expert Yannik Seigneur should change that. Together they developed a clear vision. Their ultra-modern ideas inspire the company and ensure steady growth.

The first bestseller was created by chance in 1976. A colorful model. The company runs out of single-colored yarns. Out of necessity, the leftovers are strung together. This made the “boring” uniform “ropes” on the market a thing of the past.

Patrick Edlinger joins the team in 1977. He gives the brand access to sport climbing. By proactively entering the new sport, the company secures new market shares. Because Beal ropes are now also “en vogue” in the completely new, young target group.

With the introduction of its modern weaving techniques, the company conquered the world market in the early 1980s.

Growth and innovation

In 1986, the company made the leap to world market leader and remains so to this day.

1993 is the year of the ultra-classic “Iceline”. This half rope is the first of its kind. Only 8.1 mm in diameter, special weave and extremely low impact force. It is still the first choice for many alpinists today.

In 1994, the company develops the first semi-static rope. It becomes the basis for the definition of the EN 1891 standard. Aramid cordalettes and Dyneema cordalettes are also added.

In 1996, Philippe, the third generation of the family, joins the company. With him, the digitalization of the company begins at all levels.

The production of climbing harnesses is introduced in 2000. The range is expanded a little with work at heights products. For example with pulleys.

In the fall of the year, the Austrian manufacturer Edelweiss is acquired. The brand is still sold separately today.

Products for work at heights have also been available since 1996. Such as semi-static models in all diameters.The Joker 9.1 mm is introduced in 2003. The first Beal rope with triple certification.

Upheaval and digitalization of Beal rope production

In 2006, a new plant is opened in Madagascar. It is an exact copy of the production facility in France. It also has its own sewing shop. This is where, for example, the climbing harnesses and slings are made.

2007 marks the start of the “One Rope – One Tree” initiative. For every product sold, a new tree is planted in Madagascar. To date, the proud 700,000.

250,000 have grown together to form an impressive forest.

2015 sees the launch of the Gully 7.3 mm, the thinnest half-rope twin rope in the world. This will be followed by the Opera 8.5mm, the thinnest model in the world with triple certification.

2016 Beal now also offers its own carabiners. Such as steel carabiners for work at heights, snapgate carabiner for express slings etc….

The new headquarters and production facility in France.

Technical innovations from Beal ropes

The world market leader’s products have a number of unique selling points. They have been groundbreaking for the entire industry and alpine sports. Reason enough to present them below.

High dynamics – low impact force

The maximum force that acts on the anchor point in the event of a fall is the impact force. It is specified in kN.

Traditionally, this force was relatively high in classic ropes until the 1970s. Beal then began to massively improve the manufacture of its products with regard to this “problem”.

A previously unique manufacturing process was developed. It allowed a much higher dynamic of the polyamide fibers in the core.

The low impact force is still one of the main features of Joker, Opera and Co. As a rule, it is 1kN lower than that of the competition.

This makes the fall “softer” and reduces the risk of injury.

UniCore

Beal ropes are the only ones with this complex technology. The sheath is glued to the core. This means that the sheath can no longer “slip off” the core if it is damaged.

Another side effect. Even with high intensity and frequency of use, all models remain “supple” for a long time.

Dry Cover

This technology is used in the production of the rope sheath. Every single fiber of the sheath is impregnated. In addition, each individual “thread” is subjected to thermal treatment. This is known as polymerization.

This significantly improves abrasion resistance. The treatment therefore makes ropes more resistant. Against abrasion, repeated falls, heat and dust. As a result, the service life of such models is significantly increased.

Golden Dry

This treatment makes sense for all alpine activities. This is because the core is impregnated as well as the sheath.

This means that none of the fibers absorb any more water. All these models, such as Iceline, can be designated as UIAA “water repellent”.

Video production process

In the following video you can see how ropes are made at Beal. What do we like? You can see how complex the individual steps are. You can also see how many machines are involved.

How long can Beal ropes be stored and used?

The storage period for this manufacturer’s models is 10 years. The period of use depends on the frequency and intensity of use. On the manufacturer’s side, it is 5 years.

If a rope has already been stored for 5 years, it reaches its defined “storage period” of 10 years after 5 years of use.

Our Beal rope recommendations

We recommend suitable models below. Depending on your priorities, specific products will suit you!

Indoor climbing

The WALL series includes three very good models. They are all characterized by:

UniCore technology

0% rope sheath slippage

high jacket content

increased diameter for “School” and “Master” model

These properties make them very robust on the one hand. And also very resistant. Firstly, they remain “supple” for an extremely long time. Secondly, they do not curl. Thirdly, the high proportion of sheathing ensures a long service life.

There are three different diameters depending on the level of belaying techniques. They are designed for experienced, intermediate and beginner climbers.

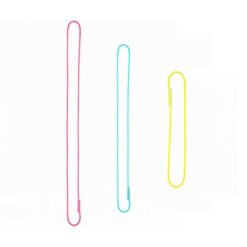

Three options with different diameters are available for the climbing hall.

Outdoor sport climbing

We recommend the following three models for outdoors.

For the absolute “crushers” among you, the 8.5mm Opera. There is no lighter rope from Beal. On the one hand, ideal for the most difficult ascents. And on the other hand for all those who love the lightest models!

The Joker 9.1mm is an ideal choice for the frequent climbers among you. Lightweight, great handling and also very durable with Dry Cover.

And for hobby climbers, the Zenith 9.5mm. It is also a good choice for “low budget” climbers. It is an inexpensive model that has proven itself very well on the market.

Beginners in particular will enjoy it. Because all belay devices are easy to use with this 9.5 mm diameter.

Our recommendation for outdoor sport climbing.

Multi-pitch

The Legend half rope – twin rope is a very good choice for multi-pitch routes. It is a model with a slightly larger diameter. It also has no expensive impregnations.

This means you get a solid product for an attractive price.

Our recommendation for beginners and multi-rope lengths, the Legend 8.3mm.

Alpine & ice climbing

Two models are particularly suitable for alpine and ice climbing. One is THE standard for many alpinists. The Iceline 7.9mm Golden Dry!

A perfect blend of diameter, safety and impact force. Plus the “water repellent” property.

This Beal half rope retains its good handling properties even in the rain and at sub-zero temperatures.

You have to look at the weight? For expeditions or extremely long routes, for example. Then the Gully is an option for you. With a diameter of just 7.3 mm, it is one of the lightest half ropes/twin ropes in the world. Also with Golden Dry!

Our two recommendations for alpine climbing. Iceline and Gully!

Big Wall Climbing

The requirements for climbing ropes on big walls are very specific. But Beal has an answer. It is called Top Gun 10.5mm with Dry Cover.

We have made a few walls ourselves in Yosemite. So we can honestly say. This model has met all requirements.

Extremely high number of standard falls

Durability due to high jacket content & dry cover

Higher diameter for better ascent with ascender

In our opinion, no big wall gear should be without it!

Our recommendation for big walls. The Top Gn 10.5mm!