What do expansion bolt think?

If you regularly use expansion bolt, you simply need to be well informed about the following topic. What do expansion bolt think? The question is often formulated with a different name for the component: What do heavy-duty anchors hold?

For this reason, we use both questions and both designations for one and the same component in the article.

What do expansion bolt think?

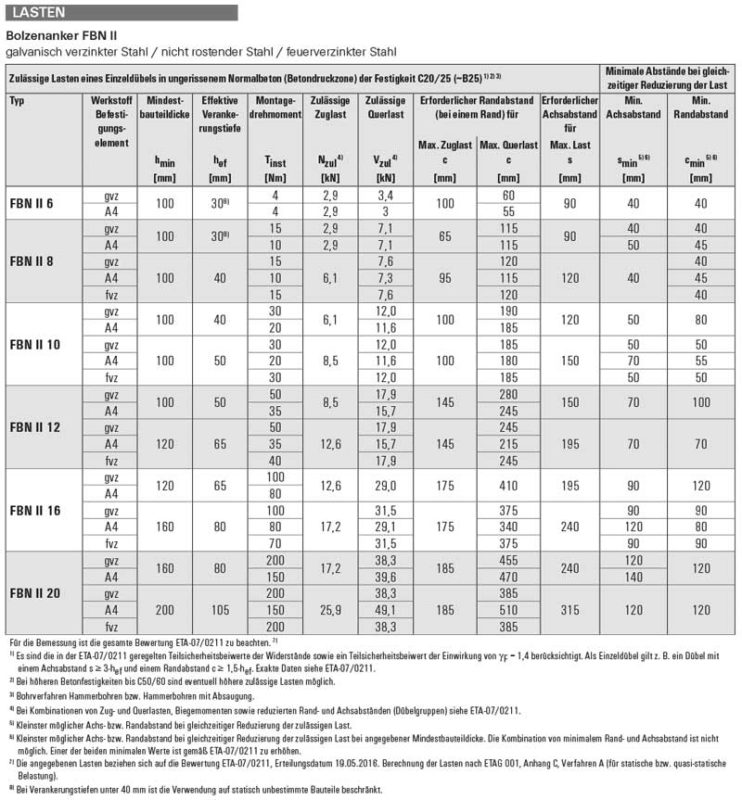

The breaking load of expansion bolt can be found in the data sheets of the respective manufacturer. These can be easily accessed on the website. The product packaging also provides further information on expansion bolt.

The following data sheets are available:

- Load table

- DOP: Declaration of Performance

- ETA: European Technical Assessment

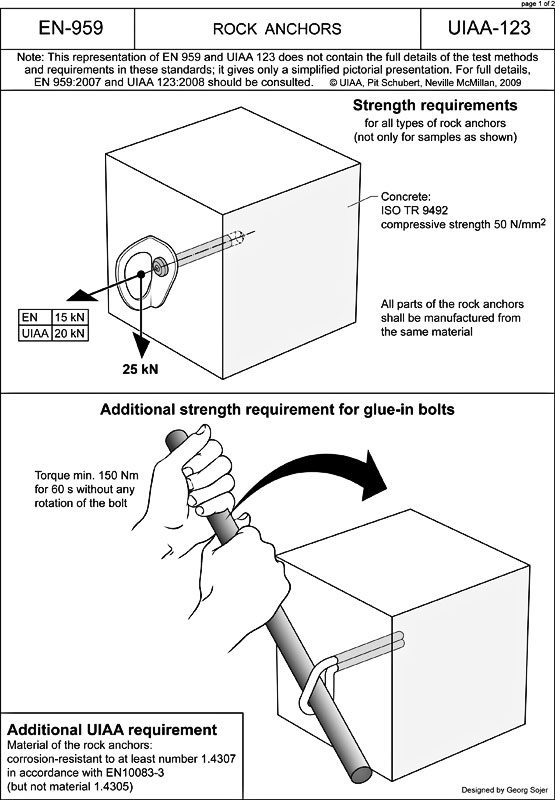

You can only find out whether a particular type of bolt complies with the EN 959 standard (see below) or the UIAA 123 standard in the data sheets.

The new EN 959 standard requires expansion bolt the following holding forces in mountain sports:

- axial (“outwards”): 15kN

- radial (“downwards”): 25kN

The UIAA 123 standard requires slightly higher axial holding forces:

- axial (“outwards”): 20kN

radial (“downwards”): 25kN

These forces can hardly ever be achieved when climbing. After all, the average force on the expansion bolt during a fall is “only” 6.5 kN.

The substrate is crucial!

Due to the high breaking load of expansion bolt can be derived for climbing.

The physical component expansion bolt or the steel fracture is not the actual risk factor.

The question “What can expansion bolt withstand?” is therefore fundamentally wrong. Rather, the question should be: “What forces can the bedrock absorb”?

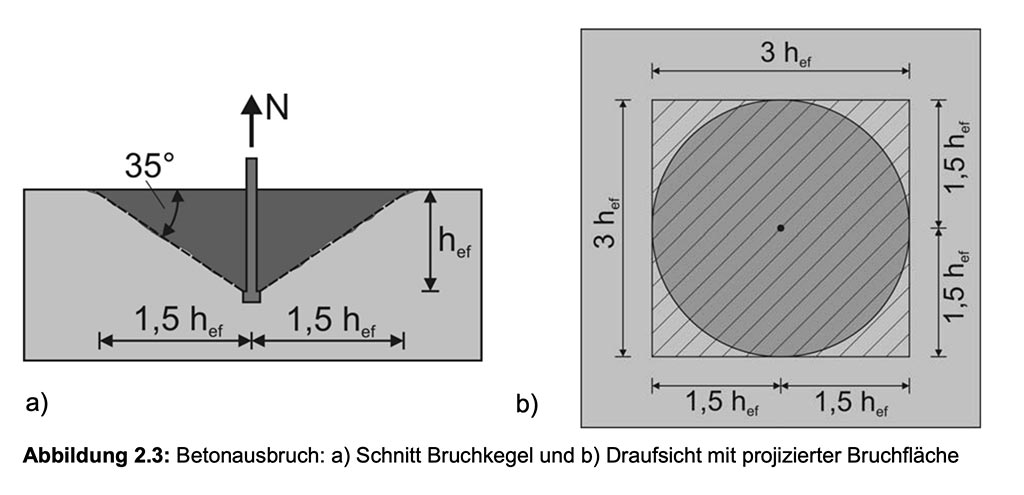

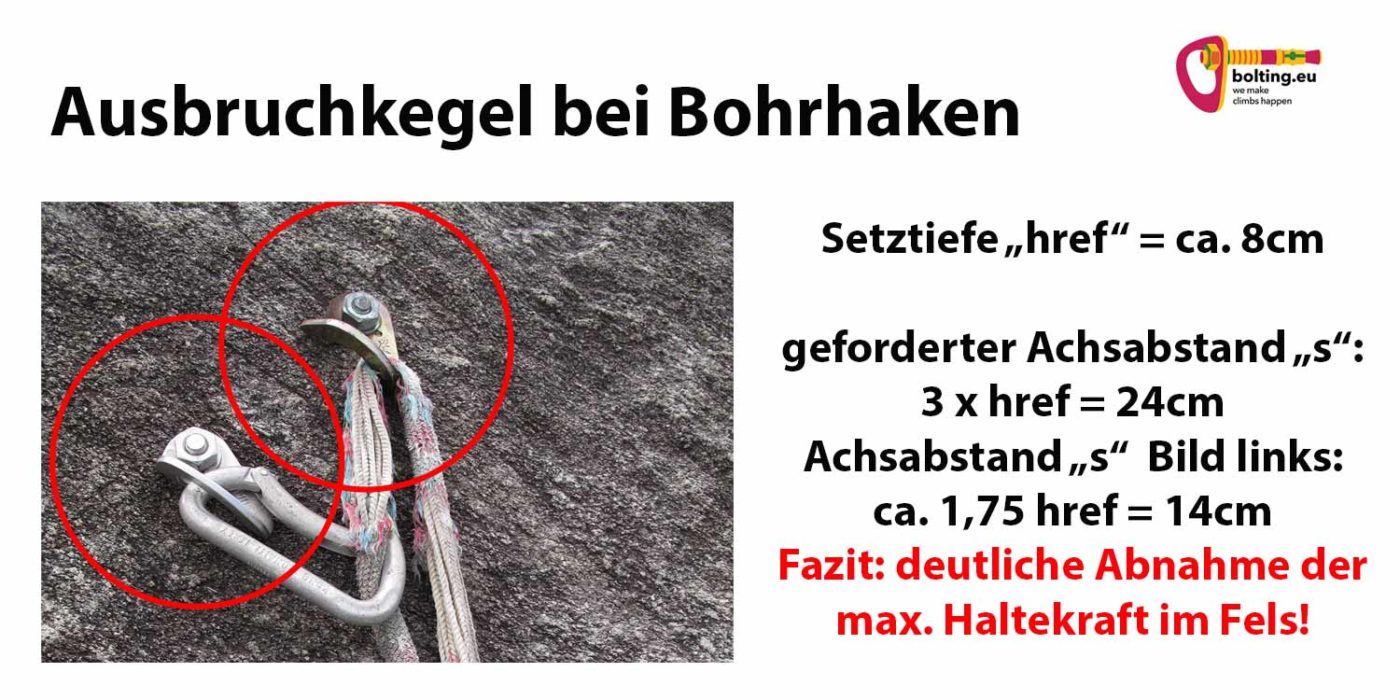

This is because the strength of the bedrock is usually the decisive criterion. In other words. If the forces are too great for the bedrock, the fixed point will fail. This failure manifests itself in the so-called “failure cone at expansion bolt”.

The question is often asked: “What do heavy-duty anchors hold?” However, this often refers to the “break-out cone”.

The breakout area depends on the following factors:

- the effective anchoring depth (setting depth) of the expansion bolt: href

- the edge distance to a rock edge: c (for “corner”)

- the center distance, i.e. the distance from one expansion bolt to the next: s (for “space”)

The following chart explains the breakout cone at expansion bolt.

Taken from: Doctoral thesis by Thorsten Hüer – University of Stuttgart 2013

Consequences for bolting

This has the following consequences for bolting a climbing route or settingexpansion bolt:

- Don’t just use any expansion bolt! Always buy your expansion bolt yourself. Also check the data sheets for the approvals and strength values.

- Only use expansion bolt in solid rock, e.g. granite or limestone. For fissured limestone, conglomerate or sandstone glue in bolt are recommended.

- “hammer test”: Check the bedrock thoroughly with a hammer. Firstly, the strength of the rock. On the other hand the sound. Cavities sound “dull” and are easy to spot!

If necessary, set a expansion bolt above the fixed link. Firstly, install a screw link / Rapid link. Secondly, the extension with a piece of rope. - higher effective anchoring depth = higher strength: therefore only use “long” in lime, for example expansion bolt

- Only use short expansion bolt (setting depth 60 mm) in very solid rock such as bombproof granite!

- Maintain a distance of at least 1.5 x the anchoring depth (href) to all edges and cracks!

- Keep a distance of at least 3 x the anchoring depth (href) to the next expansion bolt at lower offs / climbing anchors / abseiling points!

What do expansion bolt think? – Torque

Would you like to set up a climbing route with expansion bolt ?

Then you should know about the torque at expansion bolt.

This refers to the force with which the nut is “donned”. The torque is relatively low. For 10mm expansion bolt it is between 20 -35 Nm (Newton meters). For 12mm expansion bolt it is between 40-55Nm. You must read the corresponding value on the product packaging!

In practice, this means

- Do not “overtighten” the nut at expansion bolt

- stop after the clear “Knack-Knack” (“biting expansion limbs”)

- “Over-twisted” expansion bolt are under too much tension and can break immediately in the event of a fall

- the increased stress favors the so-called “stress corrosion”

What do expansion bolt hold – Danger of galvanic corrosion

Unfortunately, sometimes components made of different types of stainless steel are used. For example, stainless steel brackets with zinc plated expansion bolt. This leads to galvanic corrosion.

This causes the base metal to decompose and weaken. As a result, the breaking load can decrease dramatically at both bolt hanger and expansion bolt.

With correspondingly advanced corrosion, the above-mentioned 6.5 kN can already lead to breakage. This corresponds to a “hard” secured 4m fall.

You can read more about this specific topic in our lead article“Galvanic corrosion at expansion bolt“.

expansion bolt near the sea

The breaking load of expansion bolt near the sea can be damaged due to so-called “stress corrosion cracking” can be significantly reduced!

In simple terms, stresses in the material near the sea and the effects of acidic substances can have an enormous impact on expansion bolt. They then simply break at invisible cracks. What expansion bolt can then hold is often not even the weight of the body!

You can find out more about this topic in our technical article“Bolting near the sea“!

Incorrectly attached expansion bolt

When it comes to the question “What is the strength of heavy-duty anchors?”, incorrect installation can also be crucial.

The following “classic” faults can be found again and again. They can cause the steel to break due to unfavorable leverage.

- Setting angle not 90° to the rock surface: expansion bolt should be set at exactly 90° to the rock surface. “Crooked” bolts are to be avoided!

- Bolt hanger not 90° to the expansion bolt shaft: Not only the expansion bolt must be set correctly. The bolt hanger must also “sit” correctly. If this is not at 90° to the bolt shank, dangerous leverage can also be applied.

- SDS drill bit too long: Anyone using an extremely long SDS drill bit for drilling must be careful. Due to the strong rotation, the drilling hole opening can become far too large. This can result in a “wobbling” expansion bolt and undesirable leverage.

Further reading

Do you want to know more about the topic “What are heavy-duty anchors used for?”? We have further links for you here!

I found a very good doctoral thesis on the net. It also sheds light on some aspects of the issues discussed in this article.

Link tip: Doctoral thesis by Thortsen Hüer at the University of Stuttgart 2013: Load-bearing behavior of fastenings subjected to tensile stress close to the edge with the “splitting of the concrete” failure mode

Würth has also published an interesting article online.

“Dowel failure? No, thank you!

Chris Semmel from DAV Safety Research gives a good general overview of friction-locking and positive-locking bolt systems in the article “1×1 of mechanical bolts” in Bergundsteigen 1/07

A very good standard work is the brochure “expansion bolt” published by DAV Sicherheitsforschung in 2007.