Steel qualities at expansion bolt and glue in bolt

Steel qualities at expansion bolt and glue in bolt

Time and again, we stumble across a wide variety of designations and specifications for drilling materials. On the one hand, we read about stainless steel, chrome steel, stainless steel and duplex steel. And then there are the various steel grades. For example, AISI 316L and A4 steel or HCR steel. In short: it’s all quite confusing! We would therefore like to give you an overview of steel grades at expansion bolt and glue in bolt below.

Even if you don’t have to be a metallurgist to bolt a climbing route. Basic knowledge is important for several reasons. Firstly, it gives you a basic understanding of the subject. This enables you to select the right products for your drilling project, for example.

Secondly, it gives you a much better understanding of problems such as stress corrosion cracking and galvanic corrosion. And thirdly, you become aware of where the potential sources of error lie. Both when setting up climbing routes with expansion bolt. As well as when setting up climbing routes with glue in bolt.

Overview table

Below we present you with a practical overview of the steel qualities at expansion bolt and glue in bolt.

Consequently, the content also applies to lower off / climbing anchors, bolt hanger and screw links / quick links)

(although titanium is not a steel, this metal is listed here for the sake of completeness).

| German designation | americ. Designation | Corrosion resistance | Service life approx. in years | Geographical area of application |

| zinc plated steel | galvanized steel | low | 2 to 5 | nowhere if possible |

| A2 | AISI 304 | o.k. | 10 to 15 | only within the Alps |

| A4 | AISI 316 | high | 20 | up to max. 30km to the coast |

|

| AISI 316L | high | 20 | up to max. 30km to the coast |

| Duplex steel | Duplex steel | very high (especially stress corrosion) | 20 | next to industrial areas / near the sea |

| HCR steel | AISI 904L | Extremely high | 30 years | near the sea |

| Titanium | Titanium | Extremely high | 50 | directly by the sea |

Avoid galvanic corrosion at expansion bolt – bolt hanger! Therefore, never install components made of zinc plated steel directly with components made of other steel qualities.

Classification of stainless steels

Stainless steels are divided into four superordinate groups based on their crystalline structure. This helps us with the basic explanation of steel qualities at expansion bolt and glue in bolt:

- austenitic steels (chromium steels such as A4 / AISI 316 etc.)

- Ferritic steels (zinc plated expansion bolt or drill hook ash)

- Duplex steels (e.g. fixed PLX)

- martensitic steels

Only the first three groups are used for fixed points in mountain sports, such as expansion bolt, glue in bolt and lower offs.

We also know stainless steels from the group of austenitic steels under these names:

- Stainless steel

- Inox (from the French inoxydable = non-oxidizable)

- Nierosta (actually a steel brand name of ThyssenKrupp)

- VA steel (derived from an old production process called“ Austeniteexperimental melting“)

With the steel qualities at expansion bolt and glue in bolt, we are always talking about stainless steels. In simple terms, this means alloys that consist mainly of iron. On the one hand, the proportion of chromium is at least 10.5%. On the other hand, the proportion of carbon is very low. It is usually less than 0.05 percent. Furthermore, the addition of metals such as nickel, niobium or molybdenum results in different properties. For example, they influence the general corrosion resistance and resistance to pitting and stress corrosion cracking.

Ferritic steels

Ferritic steels are found in two steel grades. Firstly, as “corrosion-resistant” steel with 10.5% to 13.5% chromium. Secondly, as “medium corrosion resistant” with a chromium content of 17%. Expensive nickel is virtually absent. This is why these steels are also considerably cheaper than austenitic steels or chromium steels.

“Corrosion-resistant” steel is used in mountain sports. Such as the Fischer FBN II expansion bolt and the 10mm bolt hanger zinc plated.

Because the steel is relatively low-grade, it has to be additionally protected by a layer. Consequently, these products are “galvanized zinc plated” and therefore reasonably well protected. Of all the steel qualities at expansion bolt and glue in bolt, however, zinc-plated steel is by far the worst!

bolting.eu does offer products made of zinc plated steel. However, we only recommend them as temporary or makeshift fixed points. For example, for climbing area construction, climbing area rebolting or climbing area maintenance.

Our bestsellers are:

Austenitic steels – standard for steel grades at expansion bolt and glue in bolt

The majority of drilling materials are made from austenitic steel. This is why you probably already know them under the names “stainless steel” and “inox” or “chrome steel”.

The basis is an alloy based on iron, chromium and carbon. The desired properties are also achieved by adding nickel, molybdenum, sulphur, nitrogen,… are achieved.

The alloys obtain their corrosion resistance through so-called “passivation”. With more than 10.5% chromium by mass, a protective layer of chromium oxide forms on the surface. This prevents further oxidation.

You probably already know the names of the steel grades at expansion bolt and glue in bolt, such as A2 or A4, or AISI 304 or AISI 316.

The different abbreviations A and AISI are easily explained:

German: Ax= Austeniticsteel such as e.g. A4 steel

American: AISI xyz = American Iron Steel Institutesuch as AISI 316

The suffix “L” for AISI grades indicates the low-carbon and therefore more corrosion-resistant version. For example, AISI 316L.

Designations such as stainless steel, Inox and chrome steel generally all mean the same thing. Austenitic steels of category A2 / AISI 304 and A4 / AISI 316 / AISI 316L.

AISI 316 / AISI 316L can certainly be described as THE standard for expansion bolt and glue in bolt be called!

bolting.eu naturally stocks a wide range of products made of A4 / AISI 316 or AISI 316L steel as well as products made of A2 steel / AISI 304.

Marine Line from the company. Spacer

Raumer Climbing offers products from the so-called “Marine Line” in its range. However, this is not a new steel quality at expansion bolt and glue in bolt. Here, the standard AISI 316L steel from Raumer is simply subjected to further treatment during passivation.

Passivating acids (nitric acid and citric acid) significantly improve the protective layer even further. This reduces the free iron content. The remaining chromium thus forms an even better protective layer.

Surface from Vertical Evolution

Vertical Evolution has a double passivation as standard for all its products. This is called “Surface”.

According to the manufacturer, e is its equivalent treatment to “Marine Line”. On the one hand, however, as standard for all products. And for a much better price.

HCR steel – the best of the steel qualities at expansion bolt and glue in bolt

The highest quality grade of austenitic steels / stainless steels for drilling materials is AISI 904L. Also known as HCR steel. This is by far the best steel quality for bolting. (Note: Titanium = not a steel but a completely different metal!)

Molybdenum (4-5%) and copper (1-2%) have been added to HCR / AISI 904L steel. On the one hand, this makes it highly resistant to chlorine and sulphuric acids. On the other hand, breakage due to stress corrosion cracking (SCC) caused by chlorine-containing substances is prevented. HCR products are also extremely resistant to pitting. Consequently, it is the perfect material for bolting near the sea.

However, there is one major disadvantage. Due to the many expensive alloy metals, HCR / AISI 904L steel is very expensive.

The best steel quality class is currently only available from two manufacturers. Firstly from Climbing Technology and secondly from Petzl.

bolting.eu naturally stocks some of these HCR steel drilling materials:

Duplex steels

Duplex steel occupies an interesting position when it comes to steel qualities at expansion bolt and glue in bolt. Put simply, duplex steel is a mixture of 50% ferritic and 50% austenitic steel.

This gives this steel an advantageous microstructure with high yield strength. This is approximately twice as large as A2 / AISI 304 and A4 or AISI 316, for example.

Due to these properties, duplex steels are highly resistant to breakage due to stress corrosion cracking (SCC) caused by chlorine-containing substances.

Duplex steel also has a high pitting resistance. The PRE value (Pitting Resistance Equivalent) is therefore correspondingly high. From a PRE value of 32, a steel grade is considered to be resistant to seawater.

In short. Duplex steel, along with HCR steel and titanium, could be a very good option for bolting near the coast. However, the material has not established itself on the market. It is also not recommended by the UIAA in its recommendations – despite meeting all standards.

FIXE PLX steel = Duplex steel

The Spanish manufacturer FIXE has products made of duplex steel in its range. However, it bears the proper name “PLX”. This is “Standard Duplex” of grade 2205 and material number 1.4462. The PRE value is 33.

In addition to the usual steel grades, bolting.eu also stocks some FIXE products made of Duplex / PLX .

However, production of most PLX products will be discontinued in 2021. An indication that it has not established itself on the market.

Titanium

Titanium is a metal in its own right and therefore has nothing to do with steel. Drilling materials made of titanium must therefore be considered completely separately from the topic of steel qualities at expansion bolt and glue in bolt.

In the broadest sense, however, we are concerned here with comparing the metals used in drilling materials. We are therefore listing this material for the sake of completeness.

Titanium is currently the most corrosion-resistant material for setting up climbing routes. It can therefore be used directly by the sea without hesitation. However, it is important to use a suitable injection mortar with approval for salt water.

We offer titanium drilling materials from Vertical Evolution in our store:

Summary: Steel qualities at expansion bolt and glue in bolt

To summarize, it can be stated in a simplified form:

- Worst steel quality = zinc plated steel

It is made of cheap, ferritic steel. Consequently, it must be additionally protected against corrosion by galvanizing. If possible, it should not be permanently installed anywhere.

Corresponds to UIAA Anchor Class 4 (worst of 4 classes!) for “indoor use”. - Standard steel quality = A4 or AISI 316L

Highly corrosion-resistant and inexpensive austenitic steel with a long service life. Can therefore be used anywhere in the Alpine region.

Corresponds to UIAA Anchor Class 3 (class 1 = best of 4 classes) for shoring if no “stress corrosion cracking” (SCC) is known on site.

Beware of proximity to industrial plants that emit exhaust gases containing chlorine and/or sulphur! - High steel quality = duplex steel (fixed “PLX”)

Highly corrosion-resistant duplex steel with a long service life. Can therefore be used anywhere in the Alpine region. According to the manufacturer, also near the coast.

This material is known for its increased resistance to stress corrosion cracking. However, it is not listed by the UIAA in its recommendations!

In the immediate vicinity of the sea, a significantly reduced service life compared to HCR steel is to be expected! - Highest steel quality = HCR steel (AISI 904L)

Extremely corrosion-resistant steel with maximum service life. Can therefore be used near the coast and in the immediate vicinity of the sea. Currently the highest standard in steel grades.

Corresponds to UIAA Anchor Class 2 (class 1 = best of 4 classes). I.e. for “use in environments where stress corrosion cracking rarely occurs or is suspected.

Only very few HCR steels are in Anchor Class 1. I was not able to find out which manufacturer currently falls into this category. - Perfect quality – metal titanium

Titanium is a completely different metal to steel. Consequently, it must be considered separately here. On the one hand, titanium is the most expensive material. On the other hand, it is also the best for setting up climbing routes close to the sea. In short: The real deal!

Corresponds to UIAA Anchor Class 1 (class 1 = best of 4 classes). I.e. for “use in environments where stress corrosion cracking occurs.

Also important: use certified adhesives for seawater!

Download: UIAA safety warning for expansion bolt / glue in bolt

Download: Supplement to the EN 959 – UIAA 123 expansion bolt standard

FAQs on steel grades at expansion bolt and glue in bolt

The German designation A4 steel (material no. 1.4401, chem. designation X5 CrNiMo 17-12-2) corresponds to the American designation AISI 316.

The German designation “A” comes from austenitic steel. The American designation AISI comes from American Iron Steel Institute.

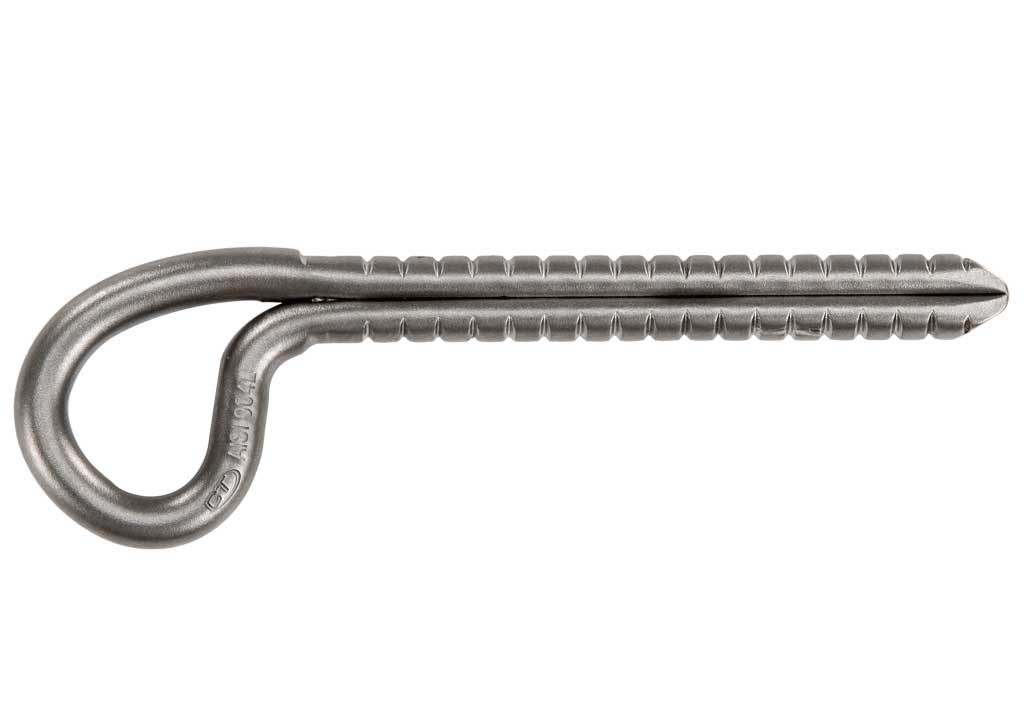

The following image shows a Fischer FBN II 10/10 A4 steel expansion bolt.

HCR steel, i.e. high corrosion resistant steel, has the AISI designation AISI 904L. It also has the material number: 1.4539

and the chemical designation: X1 NiCrMoCuN 25-20-5.

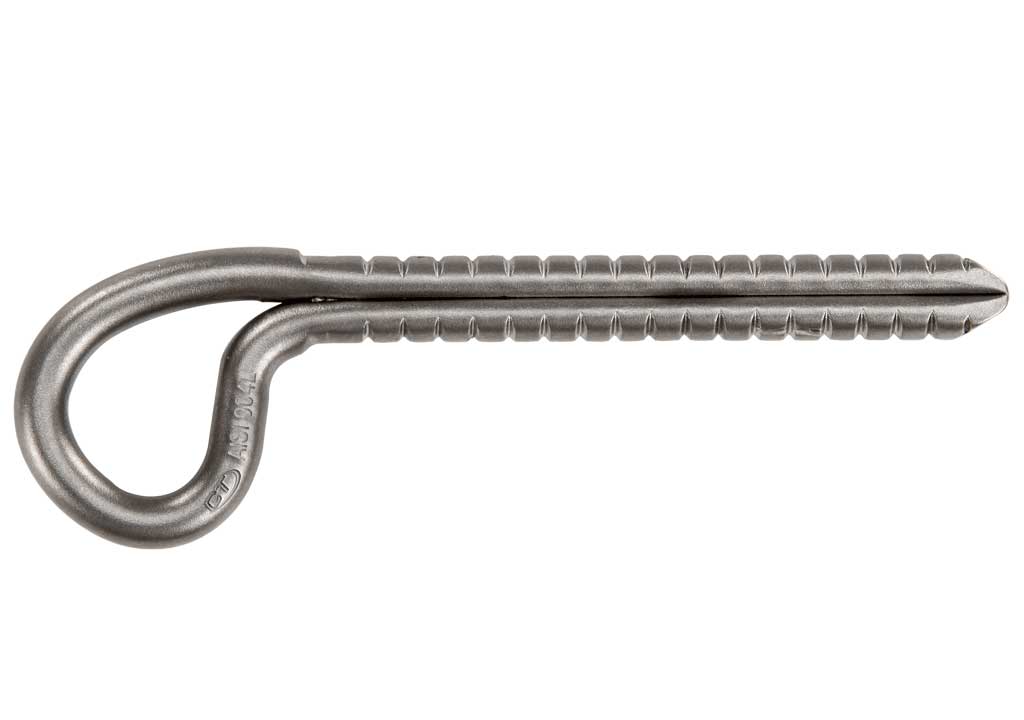

The following image shows an HCR = AISI 904L steel glue in bolt from the manufacturer “Climbing Technology”

expansion bolt for alpinism are available in the steel qualities zinc plated steel, A2 / AISI 304 steel, A4 / AISI 316 steel or A4 steel / AISI 316L steel, HCR steel / AISI 904L and duplex steel (fixed “PLX” steel).

Zinc-plated expansion bolt do not comply with EN standard 959, which requires all securing points to be made entirely of stainless steel of grade AISI 316 or higher.

Enclosed is a picture of an HCR steel / AISI 904L expansion bolt from the manufacturer Climbing Technology.

The standard at glue in bolt is A4 steel / AISI 316L steel. Consequently, you will only find more glue in bolt from these grades or higher. For example HCR steel / AISI 904L or Duplex steel (fixed “PLX steel”).

For the sake of completeness, the following overview also includes titanium, although this metal should not be counted as a steel material.