Shop » climbing anchor glue in bolt with ring

climbing anchor glue in bolt with ring

€ 29,90

incl. 20% VAT zzgl. Versandkosten

abseil anchor with 8 x 80mm glue in bolt and a ring made of AISI 316L stainless steel. Ideal for alpine routes!

Requires only a 10mm drilling hole and very little injection mortar.

Free shipping up to 2kg in

In stock

Description

Our climbing anchor glue in bolt with ring is perfect for quick installation. Because this lower off has glue in bolt with the dimension of only 8 x 80mm. This means you only need a diameter of 10mm drilling hole or a drilling depth of approx. 9cm.

You can only install this status with injection mortar install. It is unsuitable for glass mortar cartridges. We recommend it for alpine projects due to its low weight of only 368 grams.

Due to the glue in bolt dimension of 8 x 80 mm, it is suitable for all compact rock types. Finally, the flat ring also offers the option of installing a fixed steel carabiner.

In short. The perfect climbing anchor for projects with long ascents or where battery consumption is low.

Features climbing anchor glue in bolt with ring

- Manufacturer: Vertical Evolution

- Material: AISI 316L steel

- Weight: 368 gram

- glue in bolt Dimension: 8 x 80mm (drilling hole only 10mm)

- Welded ring 10mm thick / 30mm inner diameter

- breaking load 25kN

- Only to be installed with injection mortar

- Ideal for installing fixed carabiners

Perfect for alpine routes

Our climbing anchor glue in bolt with ring is perfect for alpine projects that need to be glued. This is because the stand weighs just 368 grams and has glue in bolt with a thickness of just 8 mm.

This means firstly only 10mm drilling hole width. Secondly, low battery consumption. And thirdly, only low injection mortar consumption. So you can be relatively “light” on the road here.

10 stands with the adhesive and squeeze gun add up to just 5 kg.

climbing anchor glue in bolt with ring = Longlife

Our stand is made of high-quality AISI 316L stainless steel. It also has a double passivation. This means it has an extra thick corrosion protection layer.

Compared to other manufacturers, this treatment (double acid bath) is standard with us and does not cost a cent extra. It guarantees an extremely long service life, which in the Alpine region is many decades.

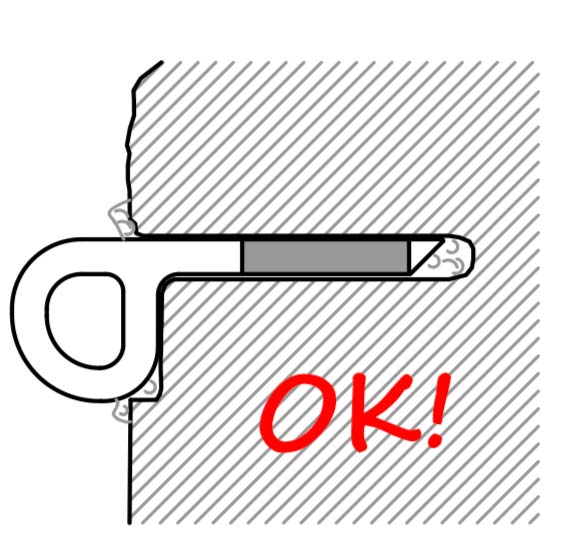

Correct installation

The climbing anchor glue in bolt with ring must, like all materials to be bonded, be processed with the utmost care. With this hook dimension, the rock substrate should be properly compact. For example, porous conglomerate or sandstone are not suitable for this small dimension. Solid limestone, slate or gneiss / granite are best suited.

Clean drilling hole cleaning with a brush and blow out pumb is crucial. Carry out at least three cleaning processes in each case!

Then drill out the channel on the side of the rock for the hook eye to protect the hook against axial twisting. Fill in enough injection mortar so that it swells nicely. Lubricate the hook eye and you’re done!

Additional information

| Weight | 368 g |

|---|---|

| Dimensions | 10 × 5 × 3 cm |

| Marke | Vertical Evolution |

| Stahlqualität | A4 steel / AISI 316(L) |

| Einbohrmaterial Kategorie | lower off & climbing anchors |

| Klebehaken Dimension | 8 x 80mm |

| Einbohr Gewicht | light |

| weitere Eigenschaften | bolting.eu Bestseller, bolting.eu recommendation, Made in Italy |

8 x 80mm - AISI 316L

Ähnliche Produkte

incl. VAT

incl. 20% VAT

incl. 20% VAT