Shop » bolting products » glue in bolts » 10mm glue in bolt Vertical Evolution

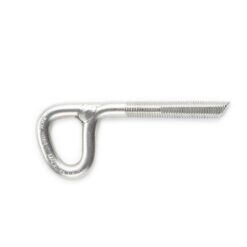

10mm glue in bolt Vertical Evolution

€ 6,49 – € 7,69

incl. VAT zzgl. Versandkosten

Our affordable glue in bolt bestseller, the 10mm models made of AISi 316L stainless steel from Vertical Evolution.

Efficient to install with 12mm drilling hole and available in three lengths: 80mm, 100mm and 120mm. As always, double passivated for extremely long service life.

Free shipping ✅ up to 2kg in

Description

This high-quality 10mm glue in bolt is made by the Italian manufacturer Vertical Evolution. It is made of highly corrosion-resistant AISI 316L stainless steel. In addition, it is made even more durable with the special “Surface” surface treatment.

Features 10mm glue in bolt Vertical Evolution

- Manufacturer: Vertical Evolution

- Dimensions: 10mm x 80mm or 10 x 100mm

- Steel: AISI 316L steel

- Passivation: double “surface” treatment for even more corrosion protection

- Weight: 130 to 150 grams

- breaking load: 30kN

- required drilling hole diameter: 12mm

- recommended drilling hole depth: hook length + 10mm

Areas of application glue in bolt Vertical Evolution

The positive product properties and the EN 959 standard make the hook a perfect hook for the following applications:

Lightweight and efficient

The processing of our glue in bolt is very efficient due to its dimensions. Firstly, it is relatively light. Secondly, the drilling hole only needs to be 12mm wide. Thirdly, the drilling depth is only 90mm or 110mm. All these features make this hook very popular and it is one of our top sellers.

10mm glue in bolt Vertical Evolution and Rapid links

Do you want to attach a screw link / quick link to the hook? Use the hook as a lower off / abseil anchor? To avoid galvanic corrosion, only use links made of A4 steel / AISI 316(L).

In our technical article“Steel qualities at expansion bolt and glue in bolt ” you can get a more in-depth insight if you like!

Set 10mm glue in bolt Vertical Evolution correctly!

If you want to bolt a climbing route, you should be very careful. This is because setting up a climbing route with glue in bolt harbors the potential for mistakes.

Firstly, start with a high-quality SDS drill bit. This is the only way to get an exact, round drilling hole. For example, use the Fischer Quattric II. This is the only way to achieve an even contact with the injection mortar.

Secondly, the borehole cleaning is done meticulously. Firstly, remove the drilling dust with the drilling hole blow out pumb out. Secondly, make further cleaning passes with the hole brush or Fischer brush. Thirdly, blow out again, voila!

Drill hole diameter when used injection mortar

The 10mm glue in bolt Vertical Evolution requires a drill diameter of +2mm to the hook diameter.

| Hook dimension | drilling hole Diameter | min. drilling depth |

| 10 x 80mm | 12mm | 90mm |

| 10 x 100mm | 12mm | 110mm |

drilling hole Diameter when using glass mortar cartridges

In this case, the glue in bolt Vertical Evolution requires a drill diameter of +4mm to the hook diameter.

| Hook dimension | drilling hole Diameter | min. drilling depth | Glass mortar cartridge |

| 10 x 80mm | 14mm | 90mm | Fischer RM 12 |

| 10 x 100mm | 14mm | 110mm | Fischer Rm 12 |

For the large dimensions, we strongly recommend not using glass mortar cartridges. Please only use injection mortar. This is because it is no longer possible to mix the two components of the mortar cartridge properly by hand!

Countersink and glue the carabiner eyelet!

One of the most common mistakes made when using the 10mm glue in bolt Vertical Evolution is that the carabiner eye is not countersunk or glued. Hence our cautionary note.

Firstly, drill out the small channel from drilling hole vertically downwards. Then clean this slot well. After inserting the hook, spread the adhesive that oozes out well around the eyelet. This protects the hook much better, especially against radial forces!

Link Tip: expansion bolt DAV brochure

Additional information

| Weight | 130 g |

|---|---|

| Dimensions | 10 × 3 × 1 cm |

| Klebehaken Dimension | 10 x 100mm, 10 x 120mm, 10 x 80mm |

| Einbohr Gewicht | normal |

| Einsatzgebiete | Alpine region, Climbing areas |

| Routen Beanspruchung | high, Very high |

| weitere Eigenschaften | great price – performance ratio |

Product safety

Top Seller

You may also like…

incl. 20% VAT