EN 959 – UIAA 123 expansion bolt Standard

The EN 959 – UIAA 123 standard regulates the requirements for expansion bolt, bolt hanger and glue in bolt. In climbing circles, it is often referred to as the “expansion bolt standard”.

Strictly speaking, these are two different standards from two independent organizations.

Firstly, the EN standard. The “European Standard” (EN) of the standardization organization CEN. This stands for “Comité Européen de Normalisation”. The exact specification of the standard is actually EN 959: 2018. The addition refers to the corresponding (annual) version of the standard.

Secondly, the UIAA standard. The certification criteria of the “Union Internationale des Associations d’Alpinisme.

The standard regulates the following products: expansion bolt – bolt hanger and glue in bolt

-

Fischer Schwerlastanker FBN II A4 Stahl€ 1,69 – € 3,49

Fischer Schwerlastanker FBN II A4 Stahl€ 1,69 – € 3,49incl. VAT

zzgl. Versandkosten

-

10mm glue in bolt Vertical Evolution€ 6,49 – € 7,69

10mm glue in bolt Vertical Evolution€ 6,49 – € 7,69incl. VAT

zzgl. Versandkosten

-

Product on sale

Vertical Evolution bolt hanger – 4mm / AISI 316LOriginal price was: € 3,00.€ 2,70Current price is: € 2,70.

Vertical Evolution bolt hanger – 4mm / AISI 316LOriginal price was: € 3,00.€ 2,70Current price is: € 2,70.incl. VAT

How are EN 959 – UIAA 123 expansion bolt standards related?

The two certificates are linked for a simple reason. The UIAA creates and manages the only globally valid standards in the mountaineering sector. To avoid duplication, there is a cooperation agreement with CEN.

As part of this collaboration, the current UIAA certificate is based on the EN certificate. This in turn was based on the UIAA standard before the last update.

The UIAA also publishes simple graphics that explain the standard. Finally, the UIAA can deviate from the EN standard with its standard values.

Requirements EN 959 – UIAA 123

The exact details of the standard may not be published in full for copyright reasons. However, publicly available information provides various details. On the other hand, the UIAA website.

Consequently, we can specify the most important requirements here:

- Material: The fixed point may only be made of “corrosion-resistant stainless steel”. In addition, all components must be made of the same material to prevent galvanic corrosion at expansion bolt.

However, the term “stainless steel” in the expansion bolt standard is very broad. This is because “stainless steel” covers a wide range of different austenitic steel alloys. They all fall into the A2 / AISI 304 or A4 / AISI 316 steel category, for example.

More information: Steel qualities at expansion bolt and glue in bolt

The standard differentiates between the areas of application of the fixed points. Firstly, a category for use near the sea. Secondly, a category for outdoor use inland. Thirdly, a category for indoor use.

This should result in the steel grades AISI 904L (HCR steel) and fixed PLX – Duplex steel for bolting near the sea. At least A4 / AISI 316(L) for inland areas. And at least A2 / AISI 304(L) for indoor use.

Further standard details

- Breaking loads and tensile strength of the EN 959 – UIAA 123 standard:

The standard values of expansion bolt – bolt hanger combinations or glue in bolt were defined as follows:

axial: 15 kN = 1,500 kg (UIAA 20 kN = 2,000 kg)

radial: 25kn = 2,500 kg

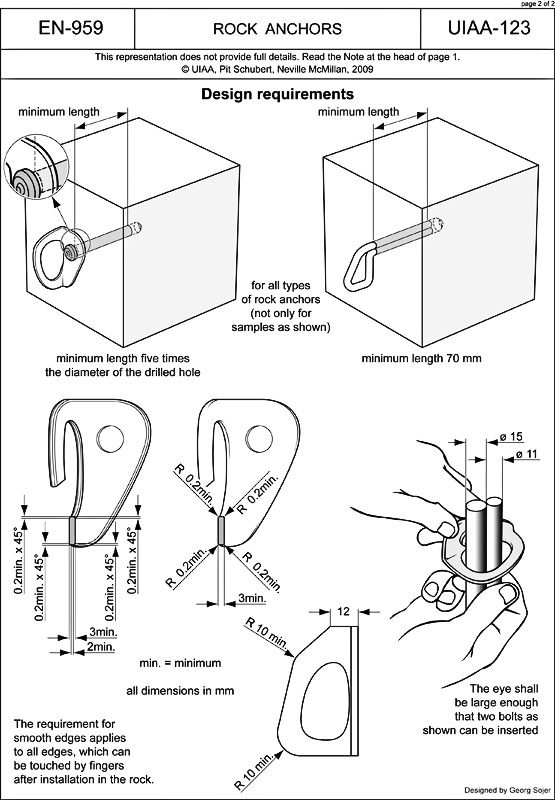

The test is carried out in a 20 x 20 cm uncracked concrete block with a certain concrete quality. The fixed points must not break or tear at the values. - Anchoring depths: On the one hand, glue in bolt must be glued in at least 70 mm. On the other hand, the anchoring depth of expansion bolt tab combinations must be at least 5 x the drill diameter.

- Drill hole depth: The fixed points must hold regardless of the drill hole depth. This means that the tests are deliberately drilled too deep.

- Eyelet shape and thickness bolt hanger: Firstly, these must be at least 3mm thick. Secondly, the edge radii must be at least 0.2mm. Thirdly, the distance from the outside to the inside at the “kink points” must be at least 10mm. Fourthly, at least 12mm at the top edge. Fifthly, a 15mm and an 11mm fastener must fit into the eyelet.

- Torque: A test with 150 Nm that starts in the carabiner eyelet must be passed. At glue in bolt this must not twist within 60 seconds.

UIAA supplementary sheet EN 959 – UIAA 123 expansion bolt Standard

In December 2020, the UIAA responded to the ongoing discussion. I.e. issued a supplement to the standard which takes further aspects into account. Such as SCC = stress corrosion cracking a.k.a. stress corrosion cracking.

Download: UIAA supplementary sheet expansion bolt standard

How do products reach their standard?

The EN 959 – UIAA 123 standard may only be awarded by authorized testing institutes. For this, however, the manufacturer must first have its production process certified.

The certificate is only awarded on the basis of a sample test if the company can provide evidence of appropriate quality management. Prerequisite: all criteria are met.

If a production company has no certification of the production process. Then random samples are taken from each production batch, all of which must pass.

Recommendations for climbing garden owners

The consequences of the EN 959 – UIAA 123 standard for climbing garden owners are quite clear. Clear recommendations can be derived from this, which can also be found, for example, in the manual for climbing areas published by the Tyrol / ÖAV.

Basically, it comes down to this. Unsurprisingly, the average care taken in equipping an “official” climbing area is based on standardized materials. Consequently, only such materials should be used for climbing area construction, climbing area rebolting and climbing area maintenance.

There is not (yet) a binding “traffic standard”. However, steel quality A4 or AISI 316L can be assumed to be the current standard. In addition, the anchoring depths of the fixed points should always be consistent with the standard.

Note: Incidentally, the EN 16869:2018-01 standard regulates the entire area much more strictly via ferrata.

For this reason, bolting.eu carries out appropriate construction documentation for all its services. On the one hand about the materials used, including technical data sheets. On the other hand, about the installation methods and implementation by a competent person. Professional documentation significantly reduces the legal risks in the event of an accident.

Buy EN 959 – UIAA 123 standard

If you want to know the full details, you have to “buy” the standard. It is available online in German from Beuth Verlag as a download for just under € 70.