Torque at expansion bolt

Torque at expansion bolt

The torque at expansion bolt is a very important thing. It is sometimes also referred to as the “torque for bolt anchors”. In simple terms, it describes the force with which a bolt should ideally be donned. The corresponding unit is “Newton meter” = Nm.

Firstly, this force must be great enough. Because only then will a expansion bolt hold properly in solid ground. And secondly, it must not be too great. Otherwise there will be too much tension in the steel and the bolt may break.

If you want to bolt a climbing route, you should definitely know about this term!

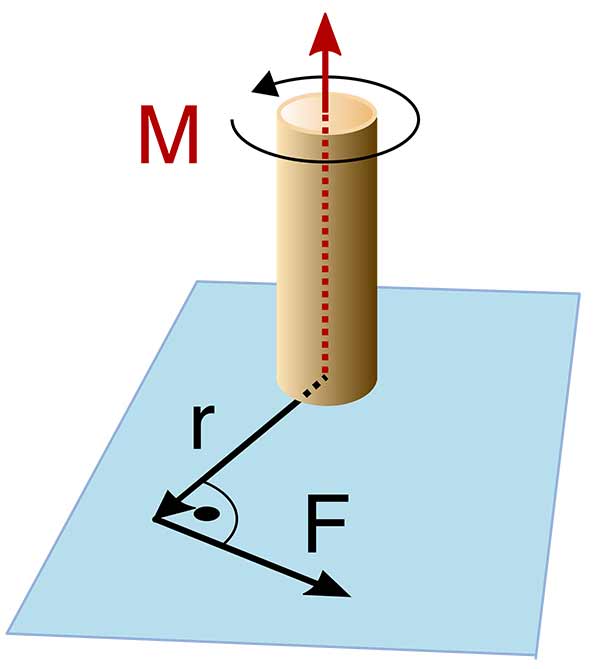

M = length of the lever “r” x force “F”:

Taken from wikipedia; graphic: Pietz

In the diagram above, “r” would therefore be the wrench. And “F” is the force with which we “donned” the expansion bolt.

The torque (“M”) is calculated as follows:

M = r x F

Torque = lever arm x force

The rock has to be right…

If you want to set up a climbing route with expansion bolt , you should be familiar with the basics. For example, the following two factors. A solid rock base and the correct torque for expansion bolt.

Firstly, the rock must be solid. With a fall factor of 2, the resulting force is approx. 6 kN. The UIAA standard 959 for expansion bolt or bolt hanger requires at least 15kN axial and 20kN radial breaking load. This means that the forces occurring almost never reach the maximum breaking load of the bolts. Consequently, if a fixed point rarely fails, it is more likely to be the rock that gives way. Not the bolt that breaks!

Further information can be found in our specialist article “What do expansion bolt hold?”

Secondly, the hook must be donned with the correct torque.

… and the torque at expansion bolt

Two things happen simultaneously with the right torque. On the one hand, the expansion links slide over the cone of the expansion bolt. In doing so, they exert the necessary expansion effect. On the other hand, the expansion bolt is also put under tension. This threshold tension only remains below a critical value with the correct torque. If it is exceeded, it will break. This is why the correct torque is so important for bolt anchors!

The Fischer FBN II, for example, has the following torque recommendation:

- FBN II 10 / 10 galvanic zinc plated: 30 Nm

- FBN II 10 / 10 A4 steel: 20 NM

The big difference is due to the different steels. The galvanized expansion bolt is ferritic steel. This means it is softer and more ductile. It can therefore be donned “more”. The A4 steel expansion bolt is made of austenitic steel. This means it is harder and more brittle. Consequently, it must not be donned as much.

You can find out more about this topic in our technical article: Steel qualities at expansion bolt and glue in bolt

When bolting at sea , even the normal swelling stress of a bolt leads to an increased risk of stress corrosion cracking.

Torque specifications

The information on the correct torque for expansion bolt can be found in two places. Firstly, on the packaging of expansion bolt. The torque is already clearly indicated here. And secondly on the manufacturer’s website. Here you will find the ETA data sheet on the one hand. And on the other hand the DOP Declaration of Performance). The correct torque is stated in both data sheets.

Conversely, this means the following. Never process expansion bolt whose origin you do not know! This has many implications. Not knowing the appropriate torque for bolt anchors is just one of them. Not knowing the steel quality is another. For example, the installation of several steel qualities and galvanic corrosion at expansion bolt is pre-programmed.

In our store you will find the appropriate expansion bolt, for which we always specify the corresponding torques. We enclose an information sheet with the product.

Theory and practice

In theory, the torque at expansion bolt should be applied correctly using a so-called “torque wrench”. However, these wrenches are heavy and unwieldy. In practice, bolters take lightweight ring wrenches or an offset 13-17 mm wrench into the wall.

The best way to find the right torque is to rely on two things. Firstly, your hearing. Everything is good when you hear the soft “click-clack” of the expansion links. Then they have slid over the cone and the bolt is holding!

Secondly, rely on your intuition in your arm. If you don’t hear a “crack-crack”, the rule of thumb applies. If the rotational resistance suddenly increases significantly, that’s enough! With a little care, you can get the right torque for bolt anchors.

Chris Semmel from DAV Safety Research put it aptly. “After tight comes off!” In other words, if you tighten the bolts really hard, you risk an immediate break!

You can of course buy the right wrenches for your project from us:

Torque at glue in bolt

If you want to set up a climbing route with glue in bolt , the torque does not play a role sheave. glue in bolt are – nomen est omen – yes, glued. It is therefore a so-called “composite system” in which there is therefore no torque.

FAQ’s Torque at expansion bolt

The torque at expansion bolt indicates the force in Newton meters (Nm) with which it may be donned. The recommendation for the torque can be found on the packaging of expansion bolt. Or, on the other hand, the approval certificates on the manufacturer’s website (ETA or DOP declaration).

The recommended torque depends on the steel quality, drill hook diameter and anchoring depth. Fischer’s recommendation for the FBN II 10/10, for example, is: 30 Nm for zinc-plated steel expansion bolt. 20 Nm for A4 steel expansion bolt.

The torque is important for two reasons Firstly, because it ensures the ideal expansion force of the expansion links. And secondly, because it prevents excessive threshold tension in the expansion bolt. If the torque is too high, the expansion bolt can break due to too much tension.

The following expansion bolt is probably broken due to excessive donning or the consequences of so-called stress corrosion cracking!

Further link: Torque on Wikipedia